Fibre Blowing Machines

TELECOMS

Through our partnership with Jetting, we supply a range of fibre blowing machines for the local telecoms market. Fibre networks are becoming more prominent for both business and domestic use. With suppliers now providing FTTH (Fibre to the Home) thus replacing existing copper infrastructure such as telephone wires and coaxial cables. Installing such fibre networks requires the need of machines called fibre blowing machines, which allow for a much faster installation of fibre optic cable over large distances rather than the traditional methods of pulling the cable through cable ducts.

What is Fibre Blowing?

Fibre cable blowing is one of the last stages in fibre projects. Fibre blowing or cable jetting is the process of blowing fibre optic cable while simultaneously pushing it through any sized duct. This is possible by using compressed air. The benefits of fibre blowing include: installing the cable along longer distances, it is less resistant to bends and undulations, there are fewer forces exerted on the cable, minimised set-up times and less manpower. Contrary to popular industry belief, fibre blowing does in fact allow the blowing of larger sized diameter cables. Fibre blowing is an efficient way to install fibre optic cables.

Jetting Fibre Blowing Machines

Established in Sweden since 2008, with a history in mechanical and industrial engineering, Jetting have developed and manufactured a series of fibre blowing machines which are reliable, robust and easy to handle. Each machine can be deployed on site within minutes ranging from handheld machines to larger cable applications with the capability of blowing fibre into ducts of varying diameter sizes. Fibre blowing is made easy with Jetting Fibre Blowing Machines.

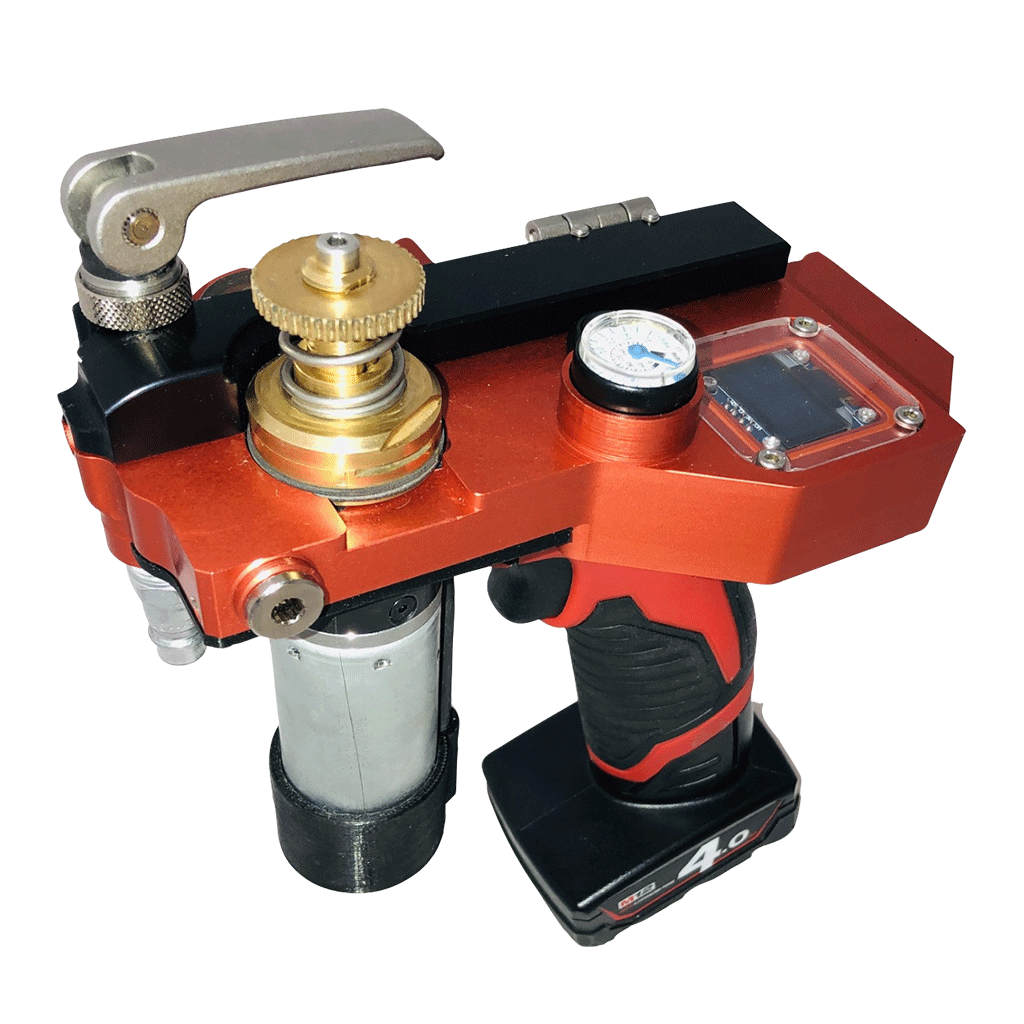

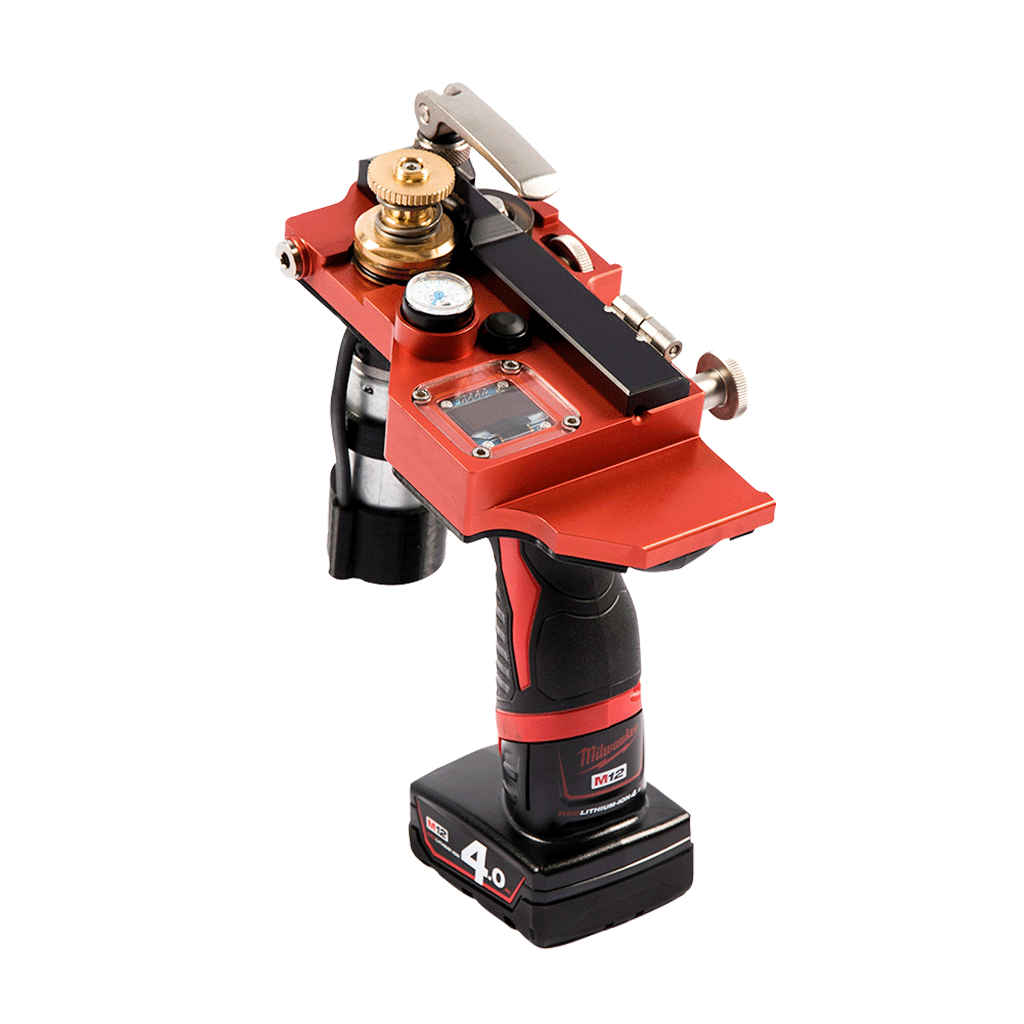

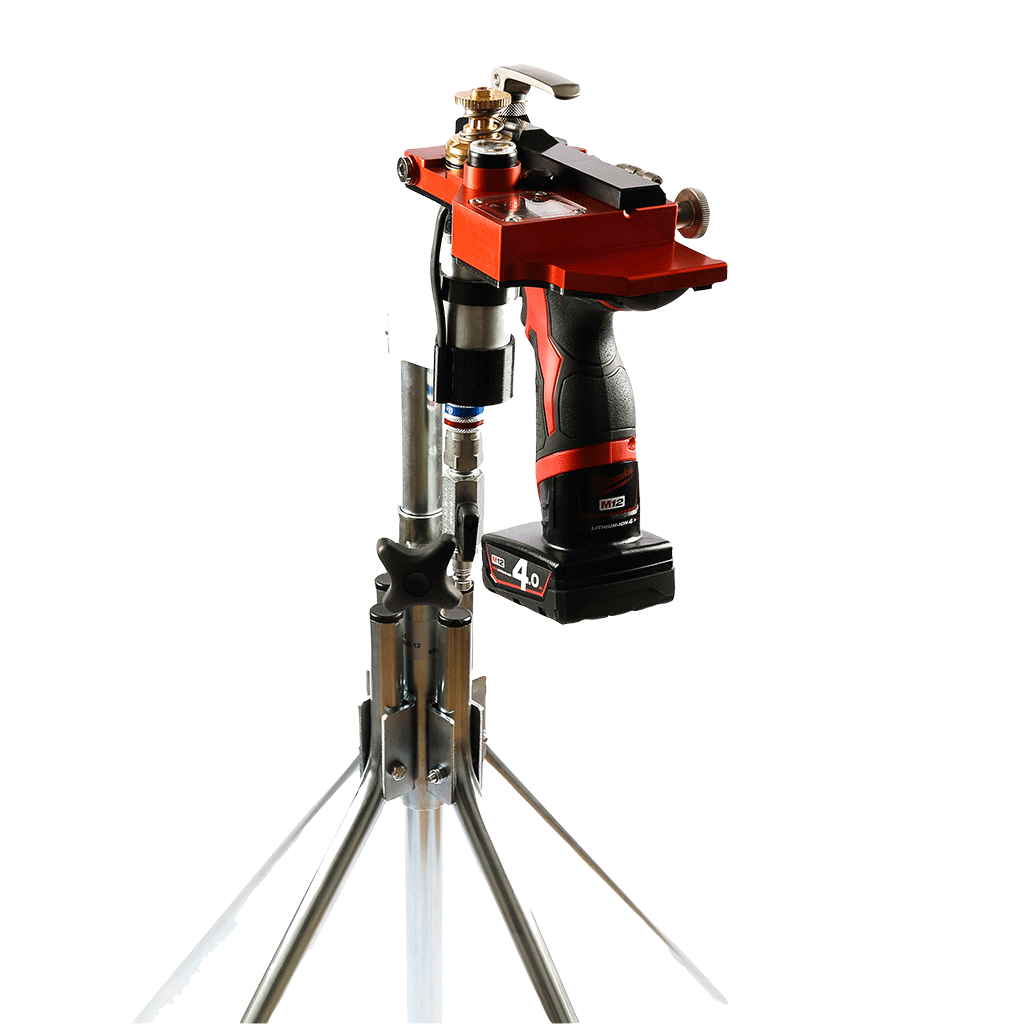

TriggAIR

TriggAIR is a robust, handheld fibre blowing machine that guides and feeds fibre cable into micro ducts by using an electric motor and with optional compressed air to reduce friction. It has an adjustable mechanical clutch, that limits the pushing force on the fibre cable to avoid damage in case of a sudden stop. TriggAIR has an air block with a maximum allowable air pressure of 16 bar and built-in duct clamps for 5.0 and 7.0mm ducts. It is fitted with a Li-ion 12V battery that powers the motor and an operated drive wheel that when combined with compressed air it installs fibre cables from 1.0 – 3.0mm at a speed of 0 to 150m/min.

TriggAIR has a built-in digital LCD Display that displays speed and distance as well as a manometer to provide full control of the fibre blowing process. It is controlled by a trigger, which can be locked in at a preferred speed and also has a reverse function to pull the cable out.

- Electrically and battery connected.

- Fibre security by mechanical clutch and adjustable clamping force.

- Forward and reverse.

- Digital display showing speed and distance.

- speed: 150 m/min.

- Max pushing force: 30N.

- Speed control

MJet V0

MJet V0 is an extremely compact fibre blowing machine that is both electrical and battery operated making it extremely portable. It is suitable for fibre cable dimensions between 0.5mm and 6mm and duct dimensions between 3mm and 16mm.

- Allows installation in a larger duct with a smaller compressor.

- The motor does not consume any airflow itself.

- Electronic stopping/slipping protection within 100 ms.

- Gentle operation, reduced cable pull with the aid of continuously variable pulling force.

- Display for current speed, distance, cable force and pressure.

- Speed: 250 m/min.

- Pushing force on cable: 60 N Continuously variable contact pressure.

- Works with JETLogger.

Another model is available – the MJet V0 HD that has a pushing force of 200N.

MJet V0 HD

MJet V0 HD is an extremely compact fibre blowing machine with electrical operation suitable for cable dimensions between 0,5 and 6,5 mm and duct dimensions up to 16 mm. Use directly from the transport case.

MJet V1

The MJet V1 is a robust and compact basic model with pneumatic operation for cable dimensions between 2.4mm and 16mm.

- Pneumatic operation with assisted double motors.

- Electronic counter for speed and distance.

- Gentle operation with long contact surface on the cable.

- Displays speed, distance, cable force and pressure in duct.

- Speed: 150 m/min.

- Pushing force on cable: 550 N.

- Continuously variable contact pressure.

- Works with JetLogger.

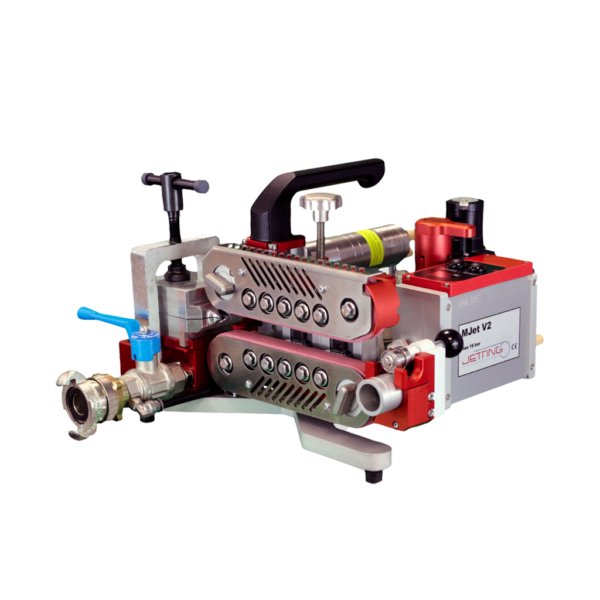

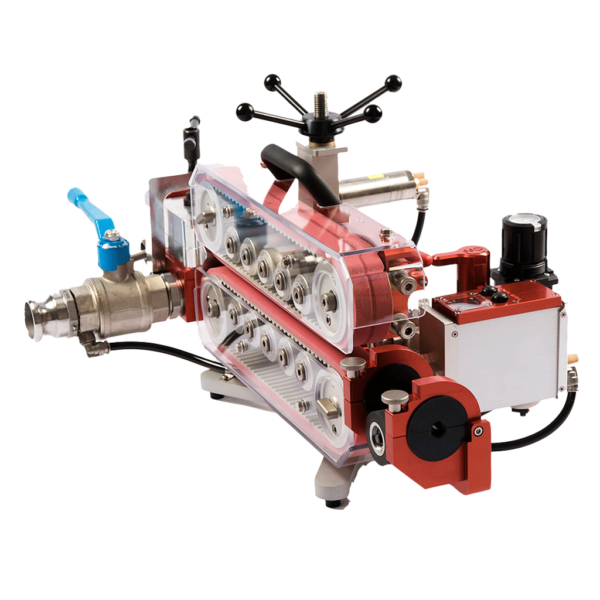

MJet V2

The updated MJet V2 is robust and compact with pneumatic operation for cable dimensions between 2.4mm and 16mm and duct dimensions between 7 and 50 mm. It operates at higher speeds at lower pushing force and with a reduced gear ratio, which makes it safer for fibre cables. When operated at normal 30-70 m/min the pushing force is less, which makes the machine very agile and forgiving for troublesome ducts.

MJet V2 comes with double parallel linear guides that eliminate play between belt drives. The belt drives are longer at 450mm, which improves their lifetime and grip. This reduces the need for clamping cables and improves performance for all cable sizes.

- Pneumatic operation with and duct dimensions between 7 and 50 mm and assisted double motors.

- Electronic counter for speed and distance.

- Gentle operation with long contact surface on the cable.

- Displays speed, distance, cable force and pressure in duct.

- Speed: 150 m/min.

- Pushing force on cable: 550 N.

- Continuously variable contact pressure.

- Works with JetLogger.

MJet V3

MJet V3 is a Pneumatically-operated fibre blowing machine for larger dimensions. Cable dimensions between 4 and 40 mm and duct dimensions between 10 and 63 mm.

- Pneumatic operation with assisted double motors.

- Electronic counter for speed and distance.

- Gentle operation with long contact surface on the cable.

- Display for speed, distance, cable force and pressure in duct.

- Speed: 120 m/min

- Max pushing force on cable 1200 N.

- Continuously variable contact pressure.

- Option of sub ducting kit makes most configurations possible. Installation can be carried out with several small microducts, for example, a 40 mm tube simultaneously.

- Works with JetLogger.

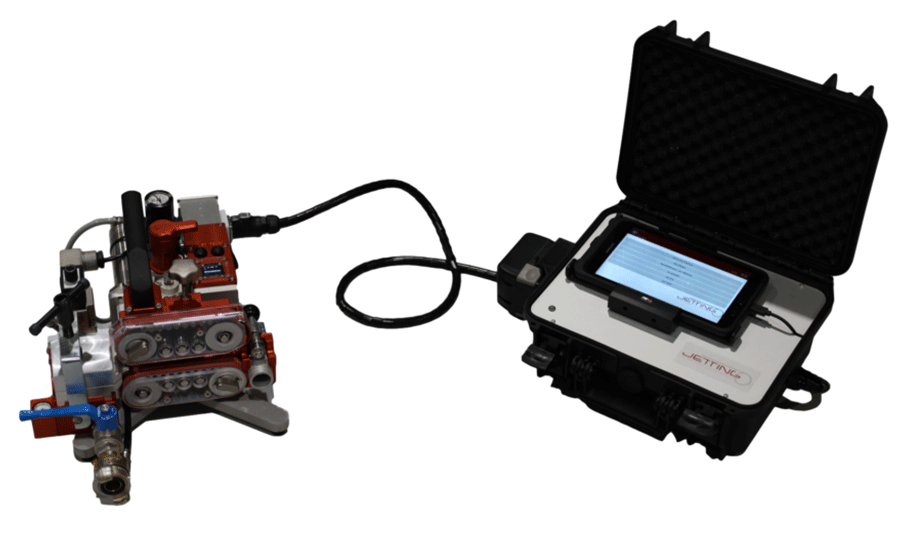

JetLogger

JetLogger is an automatic documentation system that provides an efficient documentation of the cable blowing process. JetLogger is compatible with MJet V0, MJet V0 HD, MJet V1 and MJet V3.

- Individual input describing the job, cable and pipe/duct.

- Automatic input of temperature, humidity and the exact position by GPS.

- Monitoring every 1.0 m:

- Air pressure

- Speed

- Distance

- Pushing force

- Parameters are presented live on the tablet giving the user a full overview of the process.

- Automatic safety shutdown if optimal pushing force is exceeded.

- A protocol in PDF format can be saved and can be sent to the network owner.

- Logs the type of cable and Duct used.

- Integrated GPS to locate the exact position of the cable installation via Google Maps

- Integrated 4G and SIM card slot.

- Supports all cloud services such as Dropbox, OneDrive, Google Drive and Apple iCloud

Building projects that truly matter to people.

At the heart of every project there is efficiency, reliability and scalability.